均匀设计法研究八角油β-环糊精包合物的制备工艺

【摘要】 目的 研究β-环糊精对八角油的包合作用。方法 以挥发油包合率为指标,应用3因素6水平的均匀设计法,筛选出八角油包合物的最佳制备条件,即温度、研磨时间、样品与β-CD的比例。结果实验得出最佳条件:当温度为35.0℃,研磨时间为4.0 h,八角茴香油与β-CD的比例1∶13.0( ml∶g)时,包合率为81.4%;红外测定包合作用是否完全。结论优选得到的工艺结果稳定可行。

【关键词】 八角油; β-环糊精; 包合物制备; 均匀设计

Abstract:ObjectiveTo study the inclusion complex of Star anise oil with β-cyclodextrin. Methods3 factors and 6 levels of conditions for the preparation of the inclusion complex were selected by the uniform design. The ratio of Star anise oil in the inclusion complex was used as criterion in these experiments. The inclusion complex was made by pestling method. ResultsThe best conditions of the inclusion complex were that: the ratio of Star anise oil and β-Cyclodextrin was 1:13.0(mL/g), and grinding for 4.0 hours at 35.0℃. The ratio of volatile oil in the inclusion complex was about 81.4%, and the inclusion complex was identified by IR. ConclusionThe optimized process is stable and highly efficient.

Key wordsStar anise oil;β-Cyclodextrin; Inclusion process;Uniform design

Guangxi is a Chinese autonomous province, located in a subtropical zone, south west of China. In particular, it has extensive resources of different plants. Among them, there is a special and commercial product, essential oil, which is widely recognized. Essential oils are the volatile, fragrant substances residing in the flowers, fruits, leaves, and roots of many plants[1].Most of them are a complex mixture of chemical constituents,including nitrogen and sulfur-containing molecules, aromatic chemicals, and terpenes.

The following oils are the most famous and are found in large quantity in Guangxi. Eucalyptus oi1 has been employed in ointments as a topical counter-irritant and together with menthol as an inhalation[1].Star anise oil is the main product in the fruits of Illicium verum. The plant contains remarkable essential oil, which is used as flavoring and medicine to control caught[2].The related content of trans-Cinnamaldehyde in Guangxi cinnamon oil was 11.58%, higher than that in Yunnan cinnamon oil. These two provinces are the main producing areas of cinnamon oil in China [3].

Star anise oil is separated from the fruits of Illicium verum Hook.f. This plant is used as flavorings as well as Chinese herbal medicine. In Star anise oil, anethole(structure below) is the major component which has structures as the Cis & trans isomers occurring in nature. Remarkably, the Trans isomer is always being more abundant. Star anise oil has a distinct effect on raising leucocytes (the white blood-cells), so in American patent, it has been applied in the remedy for anti-leukemia. And it also has been used as poultry feed additive composition[4]. However, the effectiveness decreases with long time storage, and both physical and chemical characteristics change relatively.

β-CyclodextrinX(structure above) has been of interest in numerous industries including the pharmaceutica1 field. This is due to their particular structures which impart interesting physiochemical properties. Today β-CD is known for their ability to molecularly encapsulate a wide variety of the drugs into their hydrophobic cavity, resulting in the enhancement of water solubility and drug dissolution's rate[1]. The results of physi cochemical tests showed that after inclusion the solubility and stability of paprika pigment, the binding ability of β-cyclodextrin for inclusion complex with guest curcumin, was improved obviously[5~7].So it is considered as a good supplementary material for injection[8].

Up to date, although the uniform design has been widely used in many synthesis and separation fields[9],no reports related with the inclusion complex of Star anise oil andβ-cyclodextrin, by three factors and six levels uniform design, has been available. However, by using this practical design, the value of Star anise oil would definitely enhance and would benefit many pharmaceutical and commercial industries.

1 Reagents

β-Cyclodextrin: was obtained from Pharmaceutical Manufacturing Factory.Shanghai;Star anise oil: was abstracted from the fruits of Illicium verum Hook.f. All the other chemicals and reagents used were of the reagent grade obtained commercially.

2 Methods

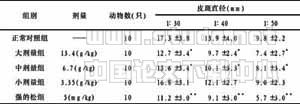

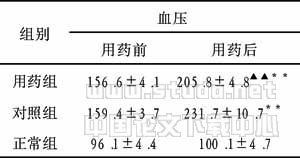

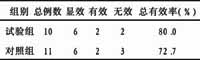

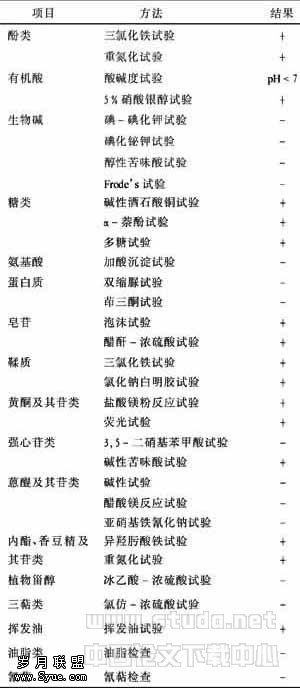

2.1 Use Uniform Design for the experimentsAmong many factors that effect the preparation of the complex, the temperature, the ratio of oil and CD, and the time to mix two compounds, are most important[10].Hence, U*(63)three factors and six levels of the uniform design was considered. To see details, in table 1.

2.2 Researches in the inclusion complex

2.2.1 The complex formation: Certain amount of β-CD was dissolved in 2~5 times of water, l ml of oil was deluded by 1ml of alcohol, and the physical mixture of the oil and β-CD was also prepared in the different ratio by gradually mixing both, ground for 1.5~4.0 hours at the same temperature.The complex was filtered and the residue (complex) was washed with 30 ml of absolute petroleum ether, 3 times.Finally kept in the desiccators until dried and the weight then recorded.

2.2.2 The instrumental error: 1 ml of pure oil was added in 500mL bottle. And followed the steps described by Chinese Pharmacopoeias (2000), the first method,calculated the error with following form and the result was 70.0%.

The instrumental error= (the volume of the pure oil after boiling/the volume of the pure oil before boiling)×100%

2.2.3 Evaluation of the complex: The β-CD and Star anise oil mixture was evaluated by the ratio of Star anise oil. And the ratio of oil was calculated by following equation:

The ratio of oil=the oil in the mixture/ (the oil added in CD*the instrumental error)×100%

Note:The rdume of the oil in the mixture was measured by the the same method in 2.2.2.

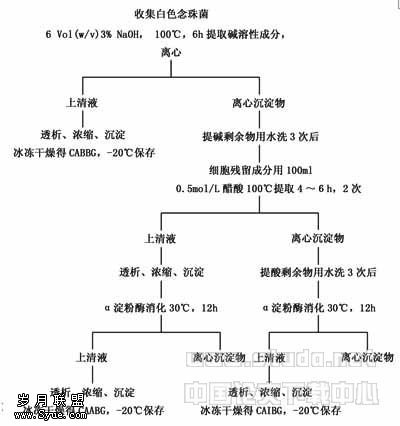

2.3 IR diffraction manifestationSince IR is a very useful tool to confirm the presence of both host and guest components[7],the inclusion complex were examined to verify the inclusion procedures had been completed by IR diffraction. Both pure chemicals and inclusion complex were examined under the same conditions.

3 Results

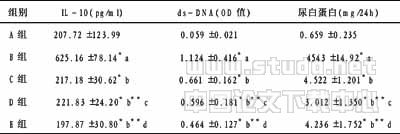

3.1 The experimental dataThe experimental data under uniform design was shown in table 1.Tab 1 Experiments of uniform design U*(63) &data table(略)

3.2 Data return analysisUsed computer technology for returning analysis, eventually got the equation and parameters as below:

I=1 B=-5.571405E-02 F=15.988 71

I=2 B=3.300 001 F=560.934 1

I=3 B=10.81882 F=2 647.349

I=6 B=-0.416 521 9 F=1 307.246 17

B=-0.4502945 F=2705.412 R=0.9999538 S=0.2815565

Y=0.450 294 5+(-5.571 405E-02)×X1+3.300 001×X2+10.818 82×X3+(-0.416 521 9)×X3×X3

(Y- the optimum ratio of oil; X1-temperature; X2-time to grind; X3-β-CD)

3.3 Search the best conditionsEmployed specialized computer software, the optimum method, for searching the best conditions to produce the inclusion complex. The results were: X1=35.0

X2=4.000 1 X3=12.965 52 Y=81.052 04

Confident internal:Y'=Y u×s

=81.1±1.96×0.218 556 5

=81.1±0.6

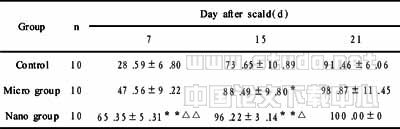

3.4 The experimental verificationVerified the results from optimum method by preparing a new inclusion complex under all factors and conditions as following: X1=35.0℃; X2=4.0 h; X3=1∶13.0(ml / g); Repeated the experiment in 2.2.2, calculated the ratio of oil from the equation in 2.2.3 81.4%.

Since the ratio of the oil reached the highest and maintained in confident internal (79.5~81.7%), the best conditions were proven reasonable and reliable. This would benefit some pharmaceutical and food industries.

3.5 IR verificationVerified by IR to prove whether the inclusion processes were properly complete or not. And the diffractograms show below (Fig1, Fig2, and Fig3). It's obvious that after inclusion, most of the typical structures which appear in star anise oil disappear. And these strongly manifest that the inclusion by CD is efficient and effective.

4 Conclusion

Uniform design for preparing star anise oil and cyclodextrin inclusion complex is reliable and practical. And the results are optimum and easy to reinforce for modern industries. Thurthermore, the stability and the ability to hide the strong smell of star anise oil after inclusion was improved obviously.

【】

[1]Dayo Abdullah,Ping Qi-neng, Liu Guo-jie[J]. Journal of China Pharmaceutical University, 1996, 27(2):77.

[2]Zhou Jie-ming,Lü Gao-rong,Zhong Xiao-qing,et al[J]. Chinese Traditional and Herbal Drugs, 2005, 28(2):106.

[3]Han Ya-ming, Jiang Lin, Huang Zheng-en, et al[J]. Central South Pharmacy, 2005, 3(4): 216.

[4]JEAN.R. Poultry feed additive composition[P].WO.9613175,1996.

[5]Lin Rong-feng,Wang Li,Liu Xiang-feng[J]. Food Research and Development, 2006, 27(3):191.

[6]Qi Ai-di, Li Li, Liu Yu[J]. Journal of Chinese Pharmaceutical Sciences,2002, 12(1):15.

[7]Wang Lu, Wang Jing-liang, Dong Chang-ming[J]. Chinese J. of Polymer Science,2006, 24(3):245.

[8]Chen Yue, Zhou Yu-1ai, Ren Yong, et al[J]. Chem. R. Chinese University,2005, 21(6):749.

[9]Joaquin Quesada, Marie Morard, Carlos Vaca-Garcia, et al[J]. Journal of the American Oil Chemists' Society,2003, 80(3):281.

[10]Zhao Xing-hua, Sheng Jia-rong[J]. China Surfactant Detergent & Cosmetics,2007, 37(2):97.